How to Build a Manufacturing Training Program that Produces Results

Only 35% of workers say their training programs are effective, based on the Report on the State of Training in Manufacturing. This comparatively low number suggests a gap in achieving the intended training objectives and addressing employees’ training needs. In turn, it leads to poor worker feedback, decreased productivity, and increased turnover.

The result? A waste of time and money.

If you’re frustrated with training programs that don’t work, this article is for you. We’ll show you how to create a manufacturing training program that helps your teams upskill, keeps your best workers safe and satisfied, improves productivity, and consequently reduces employee churn — all while keeping up with the changes in technology.

Read further to learn everything about manufacturing training programs or download a quick start guide with the common industry challenges you can address with an LMS:

5 Manufacturing Training Challenges You Can Fix with iSpring LMS [FREE GUIDE] →

What Is a Manufacturing Training Program?

A manufacturing training program is a structured educational initiative designed to equip employees with the necessary knowledge and skills to perform their jobs safely and effectively while adapting to the fast-changing nature of the industry.

Such training programs are essential to address critical issues in the manufacturing sector like skills gaps, labor shortages, and high-risk work environments. They help your team keep up with new technology, stay engaged, and feel more confident in their roles, building a more productive, performance-driven workforce for you. But most importantly, effective training and development in the manufacturing industry can save lives. So, it’s something you can’t afford to skip.

While the specific training topics depend on the organization, a manufacturing training program typically covers the following basic areas:

- Safety procedures – spotting, preventing, and reporting risks and hazards in the workplace.

- Compliance – keeping abreast of new laws and regulations, industry standards, company policies, and ethical practices.

- Lean training manufacturing – minimizing waste, the 5S methodology, and how to optimize efficiency.

- Quality control – procedures, inspection techniques, testing methods, and defect analysis.

- Industry-specific technical skills – tools like Six Sigma, etc.

- Sales training – equipping sales professionals with specialized knowledge about manufacturing processes, technical specifications, and industry-specific solutions to empower them to sell manufacturing equipment, services, and/or products to business clients more efficiently.

- Leadership – developing supervisors’ and managers’ skills in overseeing production operations, managing teams, optimizing workflows, ensuring quality control, and implementing lean manufacturing principles.

7 Steps to Create an Effective Manufacturing Training Program Online

Now that you know what a manufacturing training program should cover, it’s time to focus on how to create one that’s both engaging and effective.

While some types of manufacturing training are best learned on the job, compliance, quality control, and manufacturing health and safety training are better delivered online. In this section, we’ll show you how to create high-quality digital manufacturing skills training programs that employees will actually want to take.

Step 1. Assess training needs

Start by conducting a training needs analysis (TNA). This process helps you figure out what type of manufacturing industry training is most important at the moment — both for the business and the employee.

It doesn’t just identify skill gaps but also determines if training is the right solution for the problem or if another approach might work better. For instance, if an issue arises with operating a specific manufacturing machine, a TNA can help you decide whether a training module is needed or if the problem stems from something else, like outdated equipment.

Need help? Download this free training needs analysis template.

Step 2. Define clear learning goals and objectives

Once you’ve identified the training areas, it’s time to set learning goals and objectives for the factory worker training program. Here’s a breakdown of what you need to know.

- How many goals should I set? Start with one goal per training and define the learning objectives to help you achieve it. As a general rule, aim for around three or four objectives per goal. You may need slightly more or fewer, depending on the complexity of the topic.

- How should I structure learning goals? Use the SMART framework. Your learning objectives should be Specific, Measurable, Achievable, Relevant, and Time-bound.

- How should I communicate training goals and expectations? Make sure employees understand the business goals and expectations by including them in the description of your online training program and/or at the beginning of each course.

Let’s say you’re delivering a training module on quality control. Here’s an example of a learning objective following the SMART technique:

“Reduce machine-related accidents by 20% by the end of Q3 by providing all floor employees hands-on manufacturing safety training and clear machine operation instructions.”

Key objectives of a manufacturing training program

Almost all manufacturing training programs include the following training modules.

- Safety standards. In the manufacturing industry, safety is the most critical part of your factory training plan because it protects workers from hazards and injuries. Thus, the plan must cover everything from basic safety rules to emergency response procedures, including clear guidance on using protective gear like PPE and HAZMAT suits. Remember, regular, clear manufacturing safety training creates a safe workplace that directly improves employee retention.

- Job-specific skills for operating equipment. Since the industry relies heavily on machinery, training for manufacturing employees must teach them how to operate it properly. So, make sure your training plan covers hands-on demonstrations of basic machine controls and troubleshooting common issues. Also, don’t forget to add lessons on routine maintenance to keep the equipment running safely and smoothly. This helps to reduce employee downtime, prevent damage to the machines, and keep production training on track.

- Quality protocols and control. The quality of your company’s products must meet required standards. This part of your plan teaches employees to understand quality specs, tolerance levels, and inspection procedures. They should also learn how to spot defects in the production process, use tools like SPC (statistical process control), and identify issues early. This helps maintain high standards and boost customer satisfaction.

- Regulatory compliance. This section covers the training needed for manufacturing industry rules, such as OSHA standards, government regulations (like ISO), and certifications, to avoid legal issues. It should outline which regulations apply to each role, how often training is required, and what documents are needed to show compliance.

Step 3. Make a training plan

Once you’ve defined your objectives, the next step is to create a training plan. To make it effective and practical, work with in-house subject matter experts (SMEs) to use their knowledge and skills to ensure the training suits the job.

While you don’t need to get too bogged down in the details, your training plan should outline all the major elements of the program, including:

- Training delivery methods: Will you deliver your training program online, in person, or via blended learning?

- Learning content types: Will the training include role-plays, multimedia content, lectures, coaching, on-the-job learning, webinars, etc.?

- Evaluation method: How will you track progress and measure the overall success of your program?

- Key modules to cover: Your training plan should include the core topics and skills that need to be taught.

Effective training delivery methods

Online training. Whether through eLearning courses or live sessions, online training is great for teaching topics like safety standards and company policies. It offers engaging content like videos, interactive quizzes, and role-plays, allowing employees to learn at their own pace, making it flexible and easy to access.

Web-based online training with iSpring LMS, accessible from both mobile and desktop

An LMS like iSpring LMS is ideal for creating and delivering such manufacturing training courses. When paired with iSpring Suite, it allows you to easily design custom courses without the need for advanced design skills.

This learning platform helps you organize and update content, track employee progress, identify skills gaps, and provide useful analytics — making it especially valuable for manufacturing compliance training.All you have to do is upload your training content and organize it into personalized learning paths. Then, you can set up who will receive the training by creating groups and departments. Learners will get an enrollment notification and can simply follow the link to take the training.

Blended learning approaches. The best results are achieved when you mix eLearning with live classroom training — this method is called blended learning.

For example, manufacturing workers can take an online training course on machine safety, then watch a live demo, practice what they’ve learned, and finish with an online quiz or assessment to make sure they understand the material.

This approach helps workers learn both the basics and hands-on skills, so they can do the job confidently. It’s flexible and engaging and gives employees a well-rounded training experience.

Virtual reality (VR). Employees can wear a VR headset to practice tasks in a safe, controlled setting. This is helpful for complex or risky tasks where they need to build skills before using actual equipment. VR lets them practice without the fear of making mistakes on the job, like operating machinery or following safety steps. This memorable training ensures that workers feel more confident in real-life situations.

However, VR can be expensive, so it may not be ideal for training that changes often, like learning about new product features or updates. For example, if a company often releases new software, updating VR simulations for each version can be costly and slow. Using online tutorials or interactive demos is cheaper and faster.

Let’s look at a sample training plan.

For a higher-level visual plan, download our free manufacturing training plan template.

Step 4. Develop training content

With your plan in hand, the next step is to create your eLearning materials. These include interactive modules, videos, simulations, quizzes, and more.

If you’re not a coding expert, using an authoring tool is the quickest and easiest way to build professional-looking training material. It allows you to create interactive eLearning resources from scratch or repurpose your existing content and upload it to your manufacturing training LMS as SCORM files.

One of the most user-friendly and powerful authoring tools available is iSpring Suite. With its simple PowerPoint design and a rich library of manufacturing training program templates, you can create your first manufacturing training module in just a few minutes.

Let’s look at some examples built using iSpring Suite.

Interactions

What: Labeled graphics, timelines, glossaries, media catalogs (with multiple categories), FAQs, guided images, and 8 more.

Why: Interactions or interactive elements make microlearning content more engaging than passive learning. When learners actively interact with the material, they stay focused and understand and remember the information better.

For example, labeled graphics of a vacuum cleaner let trainees interact with its parts, like the extension pipe, to easily understand their roles and maintenance.

How: Simply choose one of iSpring’s fourteen ready-made interaction templates and customize it by adding your own content.

Quizzes

What: Short, targeted, interactive assessments to engage learners and test their knowledge about what they’ve been trained in.

Why: Quizzes motivate learners and give L&D teams valuable data on employees’ levels of knowledge.

How: You can make varied and dynamic quizzes in a snap with iSpring’s QuizMaker. It offers a variety of question types, customizable templates, and immediate feedback. QuizMaker also uses time limits, randomization, and progress tracking to create fun and effective quizzes that test understanding and recall.

For instance, you can create a quiz to check if workers understand a new machine’s operating steps.

Use multiple-choice questions to test their knowledge of the steps, fill-in-the-blank questions for important terms, and drag-and-drop tasks to see if they can put the steps in order. This not only engages your employees but also makes them well-trained and confident.

Video lectures and how-tos

Video tutorial made with iSpring

What: Digital video files that combine images, infographics, captions, and animations to teach or demonstrate complex processes or skills.

Why: Videos are an engaging way to simplify complex concepts and appeal to different learning types. They allow learners to replay content, ensuring they fully understand tasks before applying them in real-life situations.

How: Record a video lecture with iSpring Suite, then polish it with iSpring’s video editing tools. Add interactive elements like quizzes, simulations, and branching scenarios to boost learner engagement and retention.

Slide-based online courses

Use a PowerPoint-like presentation to train employees without overwhelming them.

What: A series of interactive slides with text, images, audio, video, interactions, and quizzes.

Why: This simple and intuitive format is perfect for sharing core messages and reinforcing learners’ knowledge in an engaging way.

How: Upload your existing PowerPoint slides to iSpring Suite and convert them to a SCORM course, or build a new online manufacturing training course from scratch the same way you would build a presentation.

iSpring Suite AI

Fully-stocked eLearning authoring toolkit for PowerPoint. No training required to start!

Step 5. Gather feedback

Before you formally launch it to everyone, it’s a good idea to test your manufacturing training program with a small group of employees. This helps you see how it works, fix issues like unclear instructions or technical glitches, and improve it based on the group’s feedback.

A pilot program also helps build confidence in the training and ensures everything runs smoothly when it’s rolled out to the entire team. Here’s how you can set one up.

- Identify a pilot group. This group should contain employees of different experience levels and backgrounds; it will give you the most accurate picture of how it performs.

- Explain the process. Hold a quick Q&A session to share detailed information about the goals, expectations, and the task at hand.

- Run the training. Ask the testers to carefully review the training program, focusing on clarity, functionality, and relevance, and make note of their comments.

- Collect feedback. Have them fill out a questionnaire to share their thoughts and write down any issues they noticed.

- Discuss findings. Conduct a follow-up session to go over their input and clarify doubts.

- Prioritize changes. Focus on fixing the most important issues first and save others for future updates.

Here are some sample questions to include in a feedback questionnaire:

- Did the training help you understand how to identify, correct, and prevent defects on the assembly line?

- Was it easy to navigate the training content and complete the exercises?

- Was anything missing from the course?

- Did you find the training interesting and easy to focus on?

- How long did it take you to complete the course, and was this reasonable?

- Did the course meet your expectations? If not, what improvements would you suggest?

- Was the training relevant to your daily tasks?

- Do you have any additional feedback or comments?

Step 6. Deliver the training

Once your training program is ready, it’s time to roll it out. A smooth delivery ensures that your employees will benefit from the training without disrupting their work.

- First, create your training programs using a learning management system (LMS). A well-rounded training program often includes a mix of delivery methods, like live sessions and blended formats, for maximum impact. An LMS helps you do just that, along with tracking progress and keeping your content organized.

- Build training modules that employees can access from their personal devices, from the comfort of their homes, or any other place. Flexible access to employee education material increases the chances of course completion.

- Make sure you’re clear about the deadlines and explain which ones are mandatory from the start.

- If possible, set aside quieter areas in the office for those who can take the training while on the job.

Step 7. Measure training results

Training isn’t just about delivering the content and leaving. You need to check to see if it’s effective and make modifications if it isn’t. This starts during the training session. Did the learners begin or complete courses? How many did they fail or pass? How well did they program? This info helps you figure out if the sessions are working correctly.

Learner Progress. A comprehensive training completion report of several employees.

For example, these three iSpring reports provide key information about your training program:

Course completion: See how many learners have completed a specific course. This helps gauge engagement and is also useful for auditing.

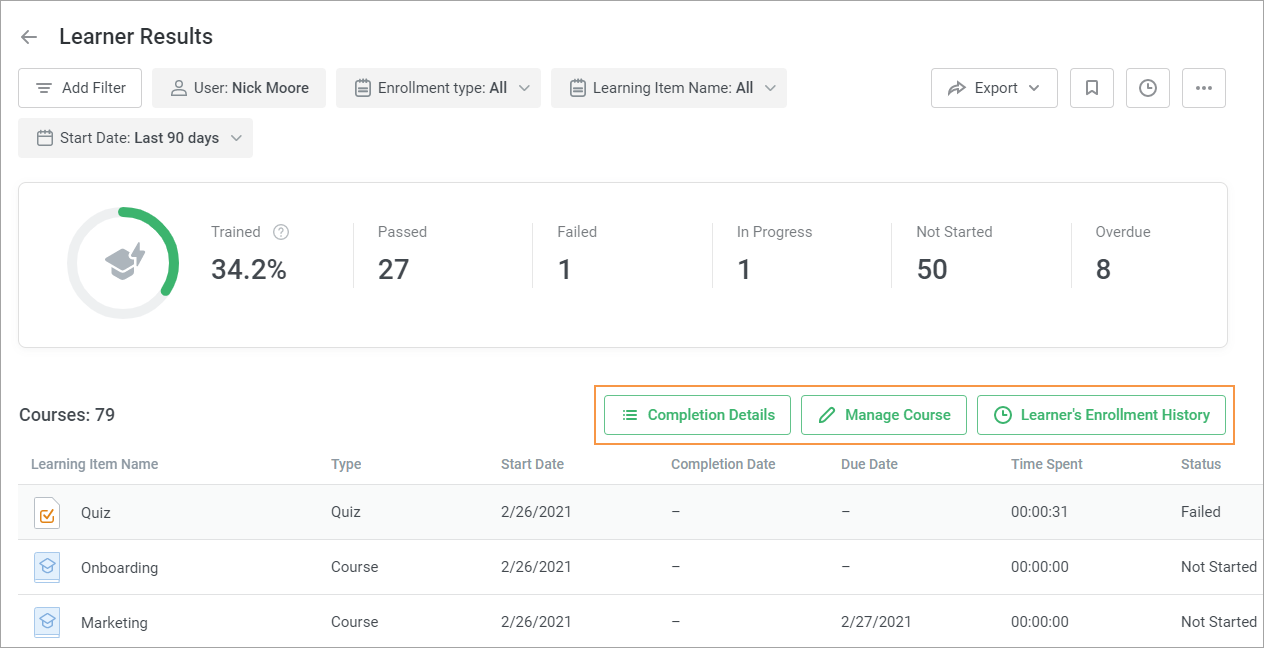

Learner progress: Monitor individual progress, including quiz scores and session times. This helps identify knowledge gaps and areas where targeted feedback or development plans are needed.

Quiz results: Analyze how learners performed on course assessments. This helps assess the training course’s effectiveness and shows where additional training or clarification might be needed.

However, these immediate metrics only tell part of the story. While they show if employees understand the material at the moment, this evaluation method doesn’t reveal whether workers actually apply these skills on the manufacturing facility floor or if the training leads to fewer accidents and better quality control.

The real impact of training shows up over time, as employees start using their new job skills.

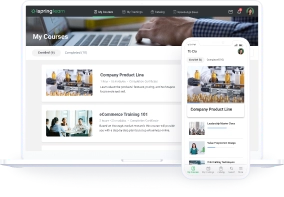

For example, an LMS like iSpring LMS has a 360-degree assessment feature that lets you see how employees’ skills improve over time. You can compare their abilities before and after participating in manufacturing training programs to measure if the employee development plan is working.

Here’s what the results look like in an LMS such as iSpring LMS:

An example of a 360-degree assessment in iSpring LMS

Documenting Training Programs for Compliance

So, you’ve trained your employees and seen their progress — but where’s the proof? What happens when higher authorities ask if your employees are compliant, and you say yes but don’t have the documentation to back it up?

This is exactly why you need to keep records of your manufacturing training — it helps you stay compliant with the relevant laws and regulations.

It shows that employees have completed required workplace safety training and are qualified for their manufacturing roles, which is often required by OSHA and other regulators. If there’s an accident or a quality issue, having training records can protect your company by proving that employees were properly trained.

But documentation isn’t just about staying compliant. It also helps you track employee progress, identify skill gaps, and ensure consistent training across shifts and locations.

This is where reporting becomes key. Compliance reporting makes sure you’ve met legal requirements, while effectiveness reporting helps you measure how well the training is working. By tracking both, you not only prove that your employees are compliant but also show that they’re prepared to perform their jobs effectively.

With a clear record of who learned what, when they learned it, and when they need a refresher, you can easily prove compliance during audits and plan your workforce better by analyzing the real-time data you’ve collected. The more detailed your training reports are, the easier it is to understand how learners are doing and what works best. The reports will help you find gaps in training, adjust learning experiences, and boost skills for better business results.

However, producing these records manually not only cuts into your precious time, but they’re also more error-prone.

Using learning management systems

The best way to document your manufacturing training program is with the help of an LMS. Why? Because your documentation needs to accomplish three main objectives, and an LMS helps you do just that. Here’s how iSpring LMS does it.

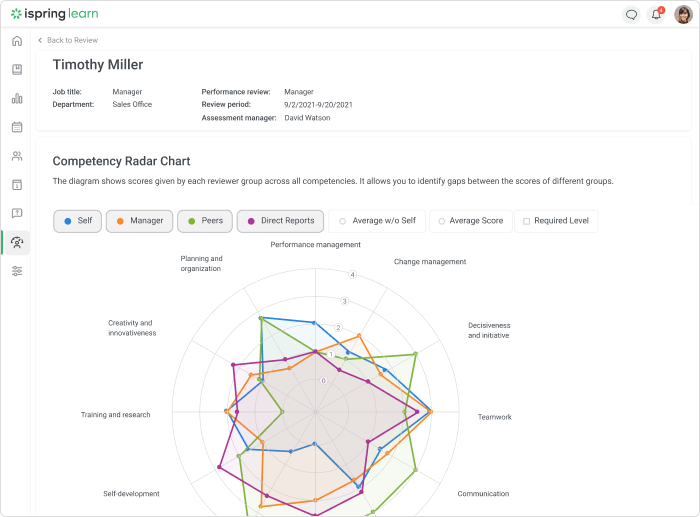

A Department Progress report showing the progress of 8 different departments

Tracking reports and certificates. With iSpring LMS’s powerful analytics and reporting features, you can easily generate detailed reports to track important training data. For example, if you need to check how a specific department is doing, you can access the Department Progress report directly and monitor metrics like training completion percentages, the number of employees that passed and failed, and how many are still pending or overdue.

iSpring also automates certificate issuance and tracks their emission and expiration dates to prevent gaps in manufacturer training and compliance. These features help keep workers up-to-date with required training, and compliance reports make it easy to show adherence during audits.

A Learner Results report showing the training completion rate of a specific employee

Individual performance. If you need more details on how an individual learner is performing, check the Learner Results report to find detailed records of completed courses, quiz and exam scores, and certifications. It shows all compliance courses assigned to an employee, including how much time they spent on each training, their progress, and how many attempts it took to pass.

These records help you track progress, identify skill gaps, and adjust training content. They also provide transparency for performance evaluations and compliance tracking.

Online storage. iSpring LMS is a cloud-based LMS that offers secure document storage for all compliance-related training materials, making it easy for employees to access the most up-to-date documents. Administrators can upload policies, procedures, and instructional materials, ensuring everyone has the latest information.

How to Automate Manufacturing Training & Development with an LMS

Documenting the training program is non-negotiable. But doing that manually? It’s tedious and keeps you from focusing on more meaningful work. One way to solve this problem is by automating manufacturing training with an LMS — not just the documentation, but the entire process.

In this section, we’ll explore how iSpring LMS can help automate training in a manufacturing environment and lighten the L&D workload.

Manufacturing training management tasks

Rather than manually enrolling learners, scheduling courses, and setting course deadlines, iSpring LMS handles it all for you. Admins can create rules to automatically enroll employees in courses based on their role, location, or other criteria.

You can automate the entire training process with iSpring LMS

Communication

You can save time by setting up automated reminders and notifications, so you don’t have to keep messaging learners. The messaging feature also lets learners contact instructors directly, facilitating communication.

iSpring keeps all communication in one place. For example, the news feed helps employees stay updated on company news and events. The interactive chart makes it easy to find the right person for a task, which is especially helpful for new hires.

iSpring’s interactive organizational chart makes it easy to find the right colleague for a task (this is especially useful for new hires).

An interactive organization chart about employees and their tasks in iSpring LMS

Learning tracks

Structured learning tracks are a great way to organize employee training or break down a complex topic into manageable units. All you have to do is combine the relevant training modules into a single path and assign them to different teams.

For example, you could create a learning track called “Safety Protocols for Machine Operators” and divide it into sections covering different safety procedures, machine handling, and emergency protocols.

Once set up, you can automatically enroll machine operators in this track based on their job function, so they’re signed up for the relevant training courses for the manufacturing industry on the specified date. This ensures they receive all necessary training without the need for manual enrollment.

iSpring LMS allows you to create personalized learning paths with flexible completion conditions.

Certification and retraining

All employers must provide regular compliance training to manufacturing employees to keep them updated on the latest rules, regulations, laws, and company practices. With iSpring, you can automate this by setting up refresher courses. Employees will automatically be enrolled when it’s time for them to retake the course.

You can also automate certification. When employees finish the course and pass the final test, the system will automatically send them a certificate to download—no need for manual work.

A completion certificate that shows the completion of a specific course.

LMS reporting

iSpring’s automated LMS reporting allows managers to track learner progress in real time without the need for manual record-keeping. They can schedule weekly reports to arrive in their inbox so they can track the metrics that matter.

Manufacturing Training FAQs

If you still have some questions about everything we’ve discussed, here are some commonly asked questions about employee training for manufacturing companies.

What are the benefits of delivering manufacturing skills training online?

Running training online has many benefits, including:

- Flexibility: Staff can learn at any time or location, making it ideal for shift workers or manufacturing employees in different time zones.

- Cost-effectiveness: Online training reduces training costs related to travel, facilities, and instructor fees.

- Consistency: It standardizes processes and procedures, making sure every employee receives the same information.

- Engagement: Interactive eLearning elements like videos, simulations, and quizzes make learning more engaging and improve knowledge retention.

- Accuracy: Digital training is easy to update, keeping content aligned with changes in processes, technology, or regulations.

How can organizations keep staff engaged during online manufacturing process training?

Here are some best practices in manufacturing training that will keep the process engaging for your staff.

- Use a variety of content, such as videos, interactive exercises, and quizzes, to meet the needs of different learning styles.

- Set clear learning objectives and expectations, and explain how the training connects to broader organizational goals.

- Provide regular feedback and support to keep employees motivated and on track.

- Include gamification elements like badges, points, and leaderboards to make learning fun.

Now, Over to You

The importance of training in the manufacturing industry is well-established — not only for upskilling and compliance but also for maintaining the safety and well-being of everyone involved in a dangerous work environment. So, if you’re running a manufacturing company and need a solid training program, the steps we’ve shared are the way to go.

Let’s quickly review the 7 stages of the manufacturing training checklist.

- Assess training needs. Identify what skills and knowledge your company and employees need.

- Define clear learning goals and objectives. Set clear targets for what the training should achieve.

- Make a training plan. Create a detailed plan for how the training will be delivered.

- Develop training content. Build the material and resources needed for the training using different types of content, like interactions, quizzes, videos, and more.

- Gather feedback. Run a pilot test before rolling it out and ask employees for their thoughts on the training to improve it.

- Deliver the training. Provide the training to your employees via online and blended learning modes.

- Measure training results. Evaluate how well the training worked and if goals were met.

Plus, don’t forget to keep records of courses, assessments, and certifications to stay organized and compliant.

It’s normal to feel overwhelmed by all the details, but there’s a solution: a learning management system (LMS) that automates the process for you.

iSpring LMS is a great solution for training your manufacturing workforce. From simulating training scenarios to building your own interactive content without leaving the iSpring ecosystem (thanks to iSpring Suite), this LMS can help you onboard new hires, close skill gaps, teach compliance, reduce costs, and improve productivity and satisfaction, all at the same time.

Don’t just take our word for it — hear it from our clients.

Here’s how one of our clients in the manufacturing industry built their training programs with iSpring LMS

A manufacturing company in Minnesota had trouble training employees across 100 retail offices, including 90 independently owned ones. They needed a way to understand what was happening at each location and make training simple and consistent for everyone, including external learners.

So, they turned to iSpring LMS, and here’s how it simplified the situation:

- It allowed the company to organize training into departments and sub-departments, which other systems couldn’t do.

- Local offices could manage their own training while staying connected, and over 50 administrators could easily add or remove employees.

- Switching to iSpring LMS was quick and easy with the help of YouTube videos.

- After uploading user lists, both administrators and learners quickly got comfortable with the system.

- Out of 4,696 users, about 1,300 actively participate in training each period.

- Many employees, especially salespeople, use the iSpring LMS app on their phones to access training.

With iSpring LMS, training became easier for local offices. It improved communication and helped keep service quality consistent across all locations.

So, why not give iSpring LMS a try and transform the way you train your employees? Try iSpring LMS with a demo and enjoy a 14-day free trial of iSpring Suite today!